|

MARPOL 73/78 Annex VI, Regulation 14.

Operation in Sulphur oxides(SOx) Emission Control Area

New and tighter fuel sulphur content regulation by EU and California Air Resources

Board,MGO Cooling Unit for the solution is applied as following:

Table: Fuel requirements for Ocean-Going Vessel Marine Diesel Engines, Auxiliary Diesel Engines

(Including Diesel-Electric) and Auxiliary Boilers.

|

Area |

Effective Date |

Fuel oil |

|

EU ports |

January 1 2010 |

Marine Gas Oil(DMA)

At or below 0.1% sulphur |

|

Within 24miles from California (CARB) |

January 1 2012 |

From 1 January 2010,This regulation applies to any use of the fuel in auxiliary engines ,

main engine, boiler for ships berthing more than 2 hours at ports in EU member States’s territory.

The California Air Resources Board (CARB) requirement for large vessel to use low sulfur MGO(Up to 0.1%)

within 24 nautical miles of the California coast.

What is existing problem?

1. ships are not designed for the distillate fuel required by CARB & EU

2. Difficult to find low sulfur diesel with sufficient viscosity for an engine to operate

3. Fuel Pump leak, due to lower viscosity and seal deterioration

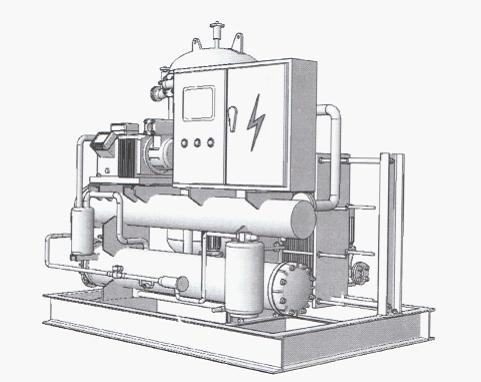

Solution→MGO cooling unit

Many factors influence the viscosity tolerance

During start and low-load operation

*Engine condition and maintenance

*Fuel pump wear

*Engine adjustment

*Actual fuel temperature in the fuel system

*Human factors, etc

Although achievable, It is difficult to optimize all the factors at the same time.

For the lowest viscosity distillates, a cooler may not be enough to cool the fuel sufficiently as

the cooling water available onboard is typically LT cooling water 360C In such a case,

it is recommended to install our MGO cooling unit.

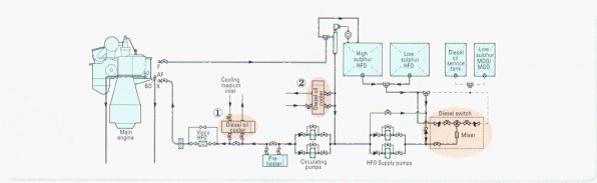

1. The advantage of installing the cooler just before the engine is that it is possible to optimize the viscosity

regulation at the engine inlet. However , The viscosity may drop below 2cst at the circulating pumps in the system

2. The coler can also be installed before the circulating pumps.

The advantage in this case is that the viscosity regulation may be optimized for both the enginer and circulating pumps.

The right location of MGO cooling unit will be decided by customers.

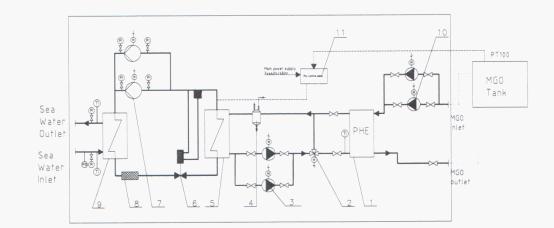

1. MGO-CW cooler 2. Three-way valve 3. Chiller water pump 4. Buffer tanks

5. Evaporator 6 . Thermal expansion valve 7. Compressor 8. Strainer.

9. condenser 10. MGO Pump 11.PLC

MGO Cooling Unit Standard Table

|

Item |

Model |

Compressor type |

Compressor

Capacity KW |

Power

KW |

Unit size

Ab. Lx W x H |

|

1 |

STMGO-20 |

4EC-6.2Y |

20 |

8 |

1000*1400*1500 |

|

2 |

STMGO-40 |

4CS-10.2Y |

40 |

16 |

1200*1600*1500 |

|

3 |

STMGO-60 |

4CS-15.2Y |

60 |

24 |

1600*1700*1800 |

|

4 |

STMGO-80 |

4J-22.2Y |

80 |

34 |

2000*1700*1800 |

|

4 |

STMGO-90 |

4H-15.2Y |

90 |

36 |

2200*1800*1800 |

|

5 |

STMGO-104 |

4G-20.2Y |

104 |

42 |

2500*2000*1800 |

|

6 |

STMGO-120 |

6J-22.2Y |

120 |

48 |

2600*2000*2100 |

|

7 |

STMGO-140 |

6H-25.2Y |

140 |

56 |

2800*2000*2100 |

|

8 |

STMGO-160 |

6G-30.2Y |

160 |

64 |

3000*2000*2100 |

|

9 |

STMGO-200 |

6F-50.2Y |

200 |

80 |

3400*2000*2100 |

|